Expanded sheet production creates practically no waste, involves shearing and stretching sheets of the base material, and produces permanent joints at the nodes. Mesh available on coil and sheet form..

Expanded sheet production creates practically no waste, involves shearing and stretching sheets of the base material, and produces permanent joints at the nodes. Mesh available on coil and sheet form..

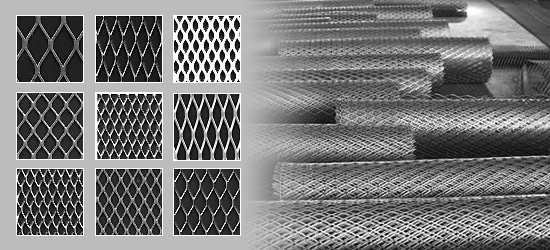

Expanded sheets make ideal solutions for a wide range of industries as decoration, grilles, air filters, sewage filters, walkway panels, shelves, compartments, baskets, partitions, fences, and various structures and devices.

1. Material quality

Standard quality of material:

- S 235JR steel plate according to MSZ EN standards

- Al 99,5 semi-solid aluminium plate

Other quality sheets can also be manufactured as long as the material can withstand the stretching process without cracking or breaking. This property should be tested by means of pilot production. In case of non-standard quality expanded sheets production the raw materials should be provided to the manufacturer.

2. Surface

The surfaces of expanded sheets comply with the standard requirements on raw materials and production processes.

3. Dimensions

Customers are requested to choose dimensions from the model list attached.

With raw materials quality described in section 1.1, the manufacturing of expanded sheets usually have the following dimension limits:

- Cold-rolled: 0.5 mm to 2.0 mm

- Hot-rolled: 2.2 mm to 4.0 mm

- Standard dimensions of original sheet: 1000 mm × 2000 mm

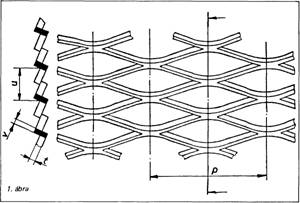

- Mesh pattern is shown on figure 1, and the long way opening is in the direction of the width of the original sheet.

4. Dimensional tolerances, requirements of form

- Long-way mesh (p) tolerance: ± 3%

- Short-way mesh (ü) tolerance: ± 10%

- Strand width (t) tolerance: ± 10%

- Sheet length (Í) tolerance: ± 10%

- Sheet thickness (v) tolerances and sheet width tolerances are governed by the relevant raw material standards.

- Camber (k) maximum: 30 mm / 1000 mm

- Crimp maximum 30 mm at up to 2.5 mm sheet thickness, and maximum 25 mm at thickness above 2.5 mm.

5. Properties at delivery

Expanded sheets receive no heat treatment after cold-drawing.

6. Batching, packaging

Expanded sheets are transported in sheets or rolled-up, and firmly secured by cork-wire.

7. Labels

All batches are labelled with the customer’s name, sheet dimensions, mesh size, and quantities.

Please note that final dimensions are calculated for 1000 mm × 2000 mm base sheets!

| Number | Marking | Sheet thickness | Strand width | Long-way mesh | Short-way mesh | Rated elongation | Length of finished product (mm) |

|---|---|---|---|---|---|---|---|

| 1 | L | 0,5 | 1,5 | 10 | 4,2 | 1,4 | 2600 |

| 2 | KN | 1 | 2 | 21 | 7,5 | 1,88 | 3500 |

| 3 | KN | 1 | 3 | 21 | 7,5 | 1,25 | 2400 |

| 3_1 | KN | 1,5 | 2 | 21 | 7,5 | 1,88 | 3500 |

| 3_2 | KN | 1,5 | 3 | 21 | 7,5 | 1,25 | 2400 |

| 4 | N | 1 | 2 | 35 | 10 | 2,5 | 5000 |

| 5 | N | 1 | 3 | 35 | 10 | 1,67 | 3200 |

| 6 | N | 1,5 | 2 | 35 | 10 | 2,5 | 5000 |

| 7 | N | 1,5 | 3 | 35 | 10 | 1,67 | 3200 |

| 8 | N | 2 | 3 | 35 | 10 | 1,67 | 3200 |

| 9 | NG | 1 | 5 | 50 | 15 | 1,5 | 2700 |

| 10 | NG | 1,5 | 3 | 50 | 15 | 2,5 | 4500 |

| Number | Marking | Sheet thickness | Strand width | Long-way mesh | Short-way mesh | Rated elongation | Length of finished product (mm) |

|---|---|---|---|---|---|---|---|

| 11 | NG | 1,5 | 4 | 50 | 15 | 1,88 | 3200 |

| 12 | NG | 2 | 3 | 50 | 15 | 2,5 | 4500 |

| 13 | NG | 2 | 4 | 50 | 15 | 1,88 | 3200 |

| 14 | NG | 2 | 5 | 50 | 15 | 1,5 | 2700 |

| 15 | NG | 3 | 3 | 50 | 15 | 2,5 | 4500 |

| 16 | NG | 3 | 4 | 50 | 15 | 1,88 | 3200 |

| 17 | NG | 3 | 5 | 50 | 15 | 1,5 | 2700 |

| 18 | G | 1 | 3 | 80 | 25 | 4,17 | 8000 |

| 19 | G | 1 | 6 | 80 | 25 | 2,08 | 4000 |

| 20 | G | 2 | 3 | 80 | 25 | 4,17 | 8000 |

| Number | Marking | Sheet thickness | Strand width | Long-way mesh | Short-way mesh | Rated elongation | Length of finished product (mm) |

|---|---|---|---|---|---|---|---|

| 21 | G | 2 | 5 | 80 | 25 | 2,5 | 5000 |

| 22 | G | 2 | 6 | 80 | 25 | 2,08 | 4000 |

| 23 | G | 2 | 7 | 80 | 25 | 1,79 | 3550 |

| 24 | G | 2 | 10 | 80 | 25 | 1,25 | 3000 |

| 25 | G | 3 | 3 | 80 | 25 | 4,17 | 8000 |

| 26 | G | 3 | 4 | 80 | 25 | 3,12 | 5950 |

| 27 | G | 3 | 5 | 80 | 25 | 2,5 | 5000 |

| 28 | G | 3 | 6 | 80 | 25 | 2,08 | 4000 |

| 29 | G | 3 | 7 | 80 | 25 | 1,79 | 3550 |

| 30 | G | 3 | 8 | 80 | 25 | 1,56 | 3350 |

| Number | Marking | Sheet thickness | Strand width | Long-way mesh | Short-way mesh | Rated elongation | Length of finished product (mm) |

|---|---|---|---|---|---|---|---|

| 31 | G | 3 | 10 | 80 | 25 | 1,25 | 3000 |

| 32 | G | 4 | 5 | 80 | 25 | 2,5 | 5000 |

| 33 | G | 4 | 6 | 80 | 25 | 2,08 | 4000 |

| 34 | G | 4 | 7 | 80 | 25 | 1,79 | 3550 |

| 35 | G | 4 | 8 | 80 | 25 | 1,56 | 3550 |

| 36 | G | 4 | 10 | 80 | 25 | 1,25 | 3000 |

| 37 | KG | 2 | 3 | 125 | 40 | 6,67 | 12400 |

| 38 | KG | 3 | 3 | 125 | 40 | 6,67 | 12400 |

| 39 | KG | 4 | 5 | 125 | 40 | 2,5 | 7400 |

| 40 | TG | 4 | 6 | 200 | 70 | 5,83 | 11000 |

Manufacturing is according to standard MSZ 05 33.2306T/84. For base sheets thicker than Lv2 the finished product is cut to size. In special cases it is possible to choose final dimensions other than the ones listed but it should always be subject to prior agreement! Quality of materials used is St 12-03 (cold-rolled, according to DIN 1623-83) for base thicknesses up to Lv 2.0, and S 235 JRG2 (hot-rolled, according to EN 10025-93) for thicknesses Lv2-Lv 4.